How to improve pipe cutting result of Exact PipeCut saws with Adjusting Wheel

The cut is affected by many factors, e.g. the size of the pipe, the material, the wall thickness, the quality of the pipe’s surface, the roundness, welded seams, blade condition, feed rate, operator’s experience, etc.

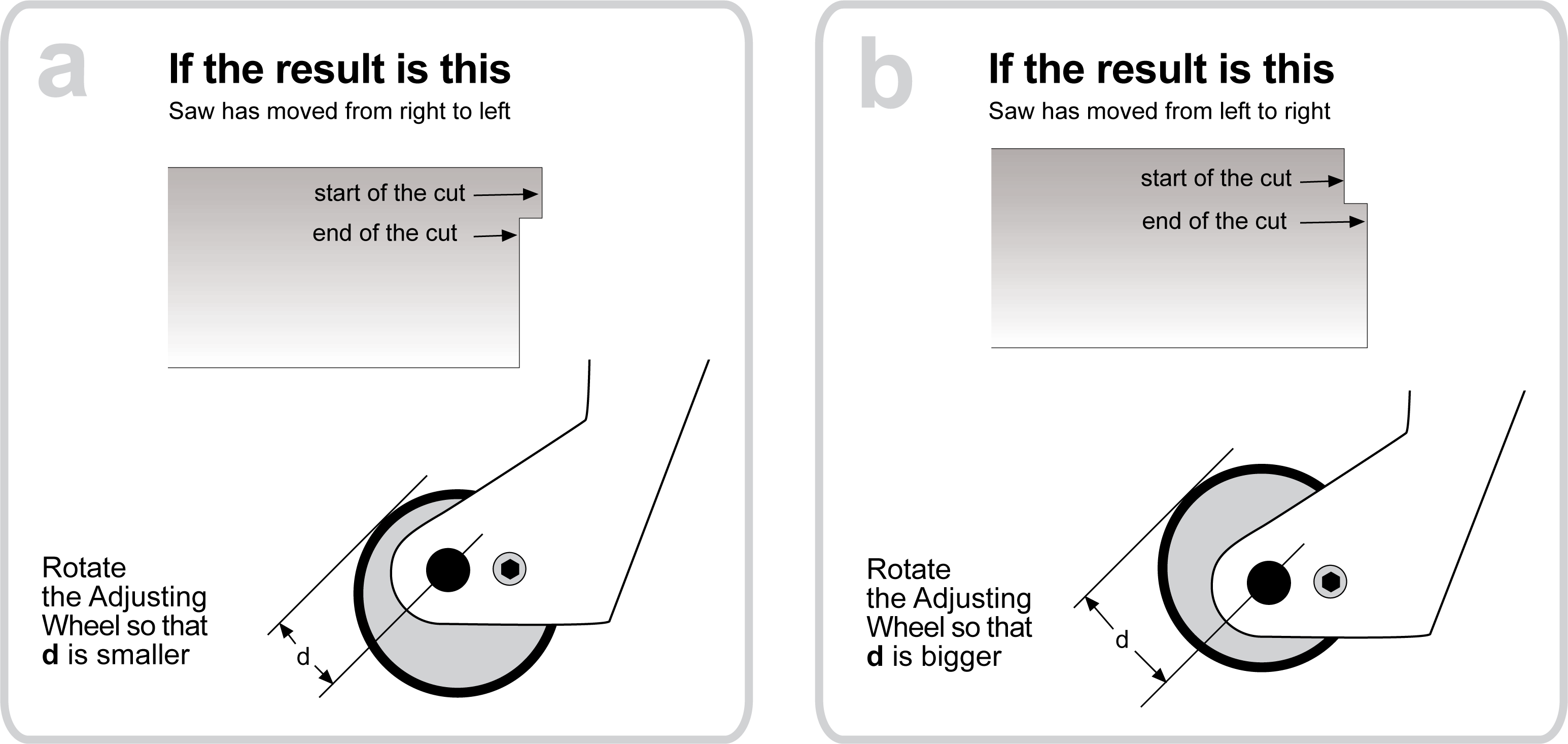

For this reason the result may vary, and the saw may move to left or right (misalignment of the cut’s starting and ending point).

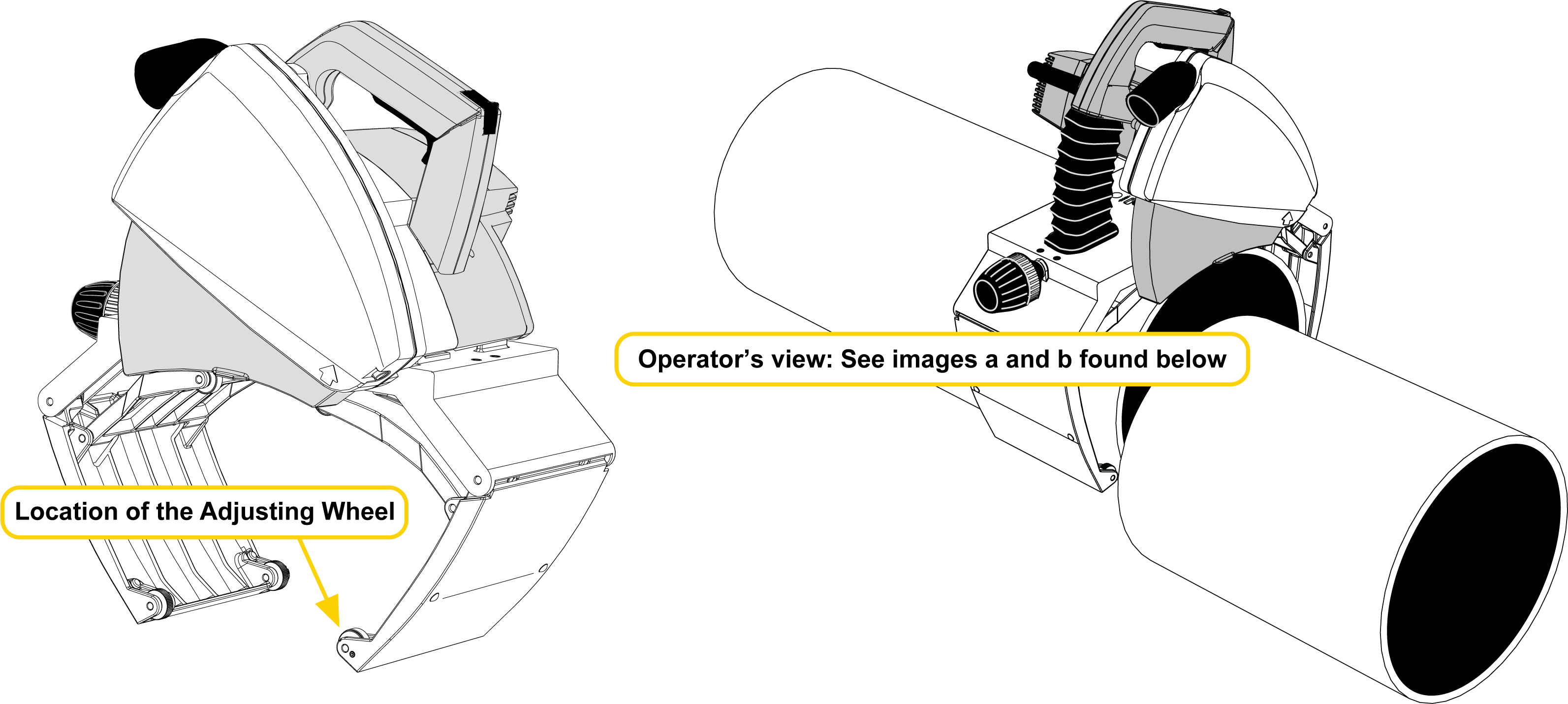

The pipe saw gripping unit has one adjustable eccentric wheel which is meant to be used for improving the quality of the cut and for reducing the misalignment. The adjustment applies only to the actual pipe size and material, and the wheel may have to be readjusted when the blade is worn.

The extent of the adjustment depends on the actual misalignment and the size of the pipe.

Remember to lubricate the Adjusting Wheel at regular intervals.

There is an allen key fixed to the handle of the saw for to loosen and tighten the socket set screw.

To adjust the wheel:

- Loosen the socket set screw.

- Turn the wheel’s center clockwise or counter clockwise to the desired position.

- Lock the wheel with the socket set screw.