The Exact Concept

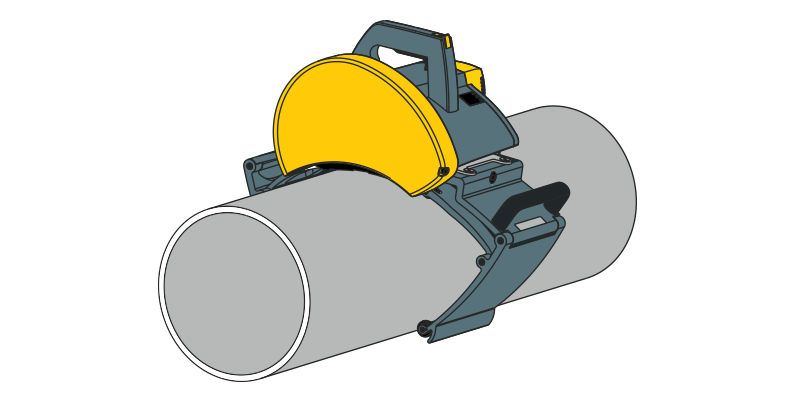

Imagine a pipe cutter and beveler that cuts your pipes fast, accurate and safely. The machines are portable, easy to operate and carry around. Appealing multi-award winner design even for your eyes. Is there much more to be asked for pipe cutting and beveling? You can now take the image from your mind into your hands and choose easier and more convenient working with all pipe works with Exact. The choice is yours.

Over the last twenty years, Exact has developed several modern and successful power tools for pipe cutting, beveling and processing. Innovative products from Exact raise the pipe working efficiency to an entirely new level.

Exact pipe cutters are suitable for all kinds of pipe materials

- Steel, Stainless steel, Acid-proof steel pipes

- Cast Iron, Ductile (nodular cast iron), Cast iron with concrete layer, Glass Fiber pipes

- Copper pipes

- Ventilation pipes

- All kinds of plastics (PE, PP, PVC etc.) pipes

Welcome to the future of Exact pipe cutting where you make more work with less effort & Forget the 100-years old way

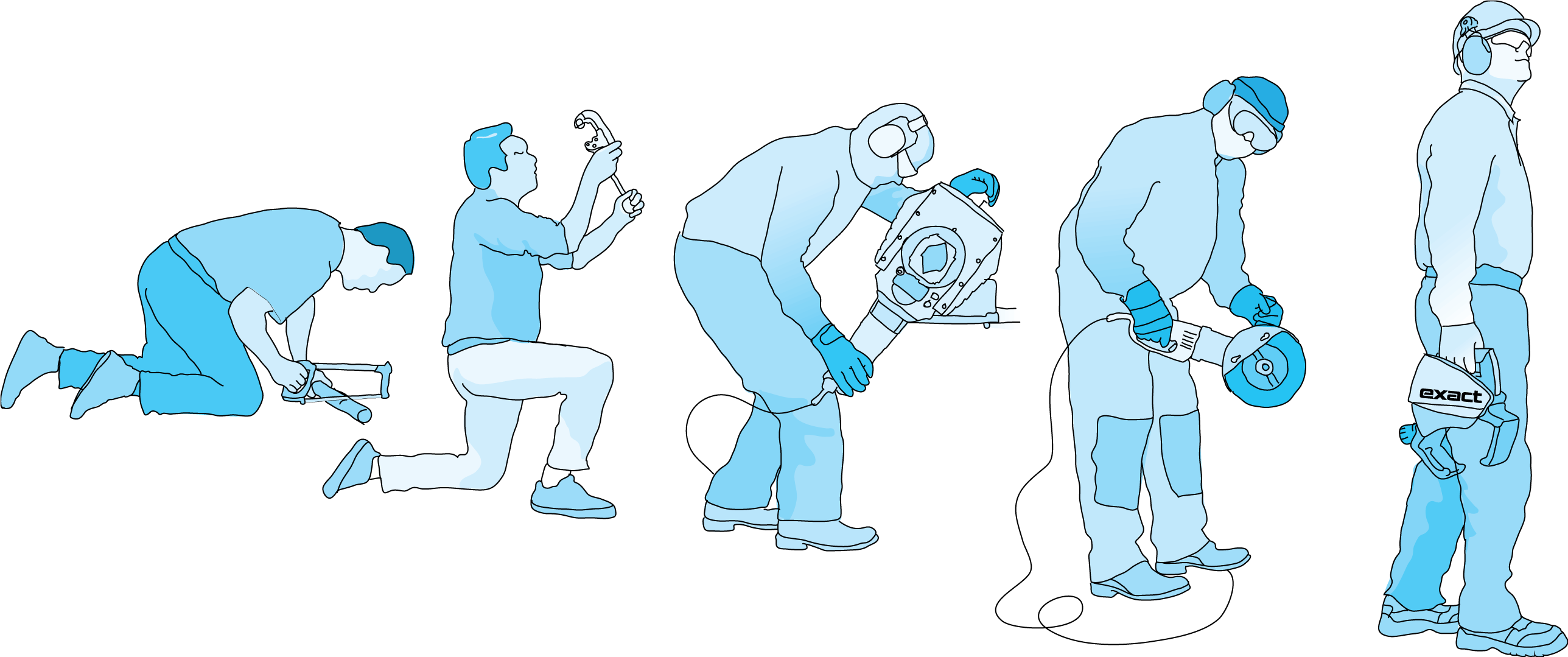

A single machine is an all-in-one solution that allows cutting or beveling pipes of greatly differing sizes. Pipe cutting is significantly faster (up to 10 times) as compared to traditional methods. The resulting pipe end surfaces are precise and of uniform quality – the pipes are ready for joining right away.

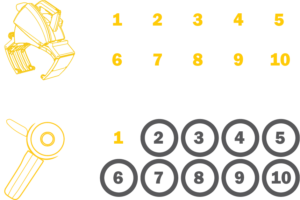

Exact pipe cutters can be used almost anywhere, since in most countries they are approved for indoor use – for example, as compared to angle grinders, the fire hazards are substantially lesser.

Exact pipe cutters are easy to move around and effortless to use, for it is not necessary to support the device while cutting. Since the cutting is fast and does not require strength, the physical work strain is very low.

The ergonomic design of Exact pipe cutters allows avoiding accidents at work and the related absences. Moreover, the risk of developing work strain-related maladies is reduced.

Efficiency and user-friendliness benefit the entire company

Quick and easy-to-use Exact pipe cutters significantly improve work efficiency. The results are of higher quality and achieved faster as compared to former methods. The high-end technology used for the electronics, motors and mechanisms ensure a very high quality, professional solution to meet most if not all requirements for very different type of pipes, jobsites and applications.

The Exact products are designed to be long-lived and easy to maintain. It is quite usual for pipe cutters commissioned ten years ago to still be in daily use.

Everybody wins: the employees feel better at work, the work progress is accelerated, and improved productivity is good for company profits.

Exact pipe cutters represent sustainable development: upon pipe processing, the tools’ power consumption may amount to only 15% of that of an angle grinder, and all tool components are recyclable. All in all, Exact pipe cutters and pipe bevelers are developed for professionals who appreciate modern solutions for multiple reasons. Some want to work with less effort, others want to be more productive in the same time window. The list goes on. We all have reasons to upgrade our way of working, but the question is – What is your reason and are you ready for the next level?

ISO

Certifications, Policy of Operation & Sustaina-bility

ISO certifications

Exact Tools Oy has operated with high quality and responsibly throughout its history. In early 2024, our company was awarded by ISO 9001 (Quality management), ISO 14001 (Environment) and ISO 45001 (Occupational Health and Safety) standard certifications.

Personal safety

Occupational safety is the fundamental of Exact Tools. In fact, it was one of the main objectives for developing the concept. The personal safety is superior to all other power tools.

The reasons behind the good personal safety lies within the good construction (gripping unit) and well-designed blade guard. The saw blade is located inside the blade guard, and it is only visible during cutting. The machine is always tightly gripped on the pipe during working process. This ensures that the cutting saw blade is limited to a very controlled area, and even if a breakdown of the machine or blade would happen, the range of motion is designed in a way that the operator is not affected, as long as safety instructions are followed correctly.

This was contrast to dangerous angle grinder which poses a real danger in case of an accident – and unfortunately, these accidents happen occasionally.

Knowingly there are no reported cases of serious (or even minor) injuries caused by Exact products.

Energy consumption

Exact is the fastest and most effective pipe cutting system on the market. The short time required to cut the pipe results in minimal energy consumption. Usually an Exact saw is 8-10 times faster than for example an angle grinder.

Absence of small particles

Exact products produce only a minimum amount of small particles to the surrounding air on job sites. This is a tremendous improvement for the air quality. Being a major health benefit to the operator, also others in the same job site minimize the inhaled amount of health hazardous small particles.

According the medical research small particles are very serious risk for your health.

Fire safety

Exact products do not produce excessive sparks like angle grinder. The chips from cutting drops below the saw and stays in the user’s field of view. It is easy to control the chips and avoid all fire risks on the job site.

Light working and minimal work strain

All Exact products are lightweight and easy to handle, move and operate. Most of the heavy-straining work is avoided thanks to the clever concept of Exact gripping unit that is part of every Exact machine.

There is no other machine that is as portable and yet lightweight to use by its concept.

Environment

Most Exact machines’ parts are recyclable. Separate recycling of used products and packaging support recycling and recovery of materials. Reusing recycled materials helps preventing the pollution of the environment. According to local regulations it is possible to deliver household appliances to municipal rubbish depositories or to the dealer when purchasing a new product.

Our History

The initial company was founded in 1993, Headquartered in Finland to this day with offices in the USA. From idea to life – The multi-award winner Exact concept springs from the end users’ desires and was nurtured from the absence of a pipe cutter that could cut pipes accurately, safely and fast – yet being lightweight and portable. Before the introduction of the Exact pipe cutting system there had been no significant innovations in pipe cutting practices for decades. Workers often had to use an angle grinder that is not only inaccurate and slow but is also a fire hazard.

Our purpose is customer-oriented approach in bringing better pipe cutter tools and making pipe cutting easier and more productive. The core of our business model has been based on our customers’ demands from our first product to this day and our whole product development is based on the voice of professionals, your voice. From life to the next level – Now 20+ years and 20 000 happy customers afterwards Exact Tools has developed, and continues to develop, countless solutions to bring more advanced power tools for pipe cutting and bevelling for high demanding conditions.

2024

EXACT TOOLS HAS OBTAINED QUALITY (ISO 9001), ENVIRONMENTAL (ISO 14001) AND WORK SAFETY (ISO 45001) CERTIFICATES

As part of our continuous improvement, Exact Tools has obtained ISO certificates that validate our commitment to customers: providing Exact, Efficient, Safe, and Ergonomic portable pipe cutting tools for professionals worldwide.

2023

NEW VISION, MISSION AND VALUES TO SUPPORT GROWTH – YOU ALWAYS GET THE EXACT EXPERIENCE

Under new management, Exact Tools has revamped its purpose, crafting a fresh vision, mission, and values that guide our growth strategy. Fearlessly challenging industry norms, we take pride in our expertise, aiming high to make a meaningful impact. Our brilliant pipe saws enhance efficiency while prioritizing safety and well-being. Leveraging our knowledge and experience, we empower companies and their employees to go for something new by challenging the old methods. Our commitment to promises and genuine interest in people’s feedback set us apart. We strive in high quality experience through exceptional service in everything we do.

2020

20 YEARS & 20K+ HAPPY CUSTOMERS

Exact Tools has developed, and continues to develop, countless solutions to bring more advanced power tools for pipe cutting and bevel-ling for high demanding conditions.

2017

HIGH END PRODUCTS

After many successful years of bringing quality power tools to the pipe cutting industry, it was time to enter the high-end product industry and industrial sector. More advanced technology for electronics, motors and mechanisms. As a result, the most advanced products are and will be launched. The outcome of the decision is our Pro Series product family and AIR series.

2012

EXACT BRAND STRATEGY

The brand strategy was changed to more customer-oriented approach from the previously used private label model. The focus is now solely in developing and improving Exact brand and listen to our customers’ voice more than ever before.

2001

REGISTRATION TO EXACT TOOLS

The company started focusing on plumbing tools to make revolutionary power tools for plumbers & provide better solutions for the whole industry. The Exact concept was released, and so was the registration of Exact Tool.

1993

INITIAL COMPANY FOUNDED

Initial company For-Man Trade Oy was founded in 1993. The main focus was trading of high-end blades

Contact us

Leave a note – our customer service will get back to you soon.