The Most Efficient Way To Cut Stainless Steel (Comparison)

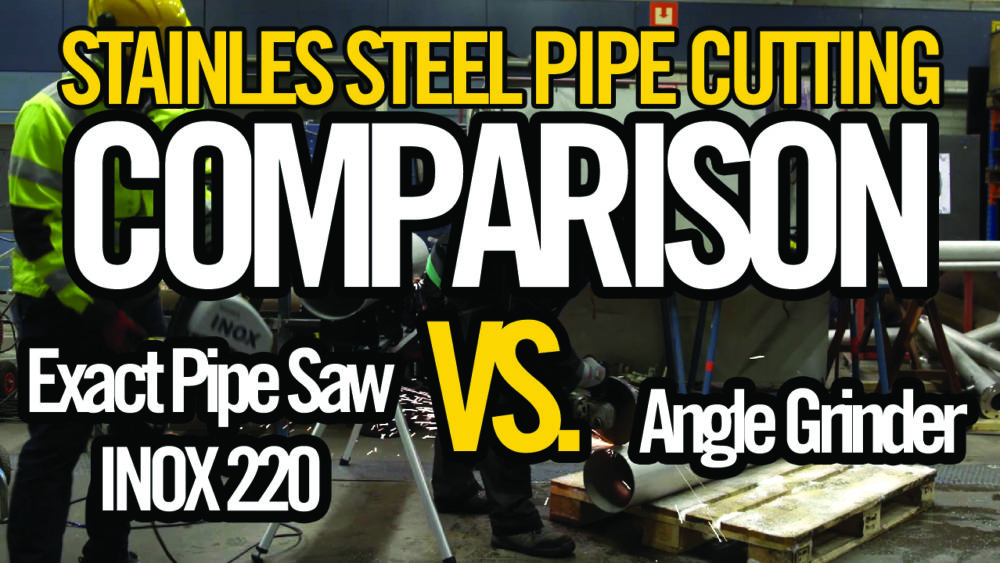

Cutting stainless steel pipe is usually a difficult and slow task, especially when the tool used for the job is angle grinder. Angle grinder is not only slow and inaccurate, but also dangerous and prone to cause accidents.

To make things more complicated, stainless steel pipe materials are challenging to cut due to their nature of material composition. As angle grinder was not really invented for pipe cutting in the first place – not to mention for challenging pipe materials – it’s no wonder that the outcome is what it is.

On the other hand, expensive and extremely heavy industrial machines are capable of cutting stainless steel pipe materials almost in a heartbeat, but the machines are usually not very user-friendly and the heavy machines are difficult to move around. This means that the pipes must be brought to the machine, instead of bringing the machine to the pipe.

This is often not very productive in environments where the work needs to be done in a versatile way, when the pipes need to be cut at specific places or when it’s just inconvenient to move the pipes around. Just to mention a few reasons.

But what if there was a solution to this. A machine that is lightweight and portable like the angle grinder, yet having the likewise power of a big industrial cutting machine?

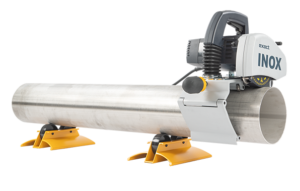

This is where Exact PipeCut 220 INOX comes in. The machine has been invented based on customer wishes for the above-mentioned reasons. Previous Exact pipe saws are able to cut stainless steel materials, but the main benefit of the new machine is it’s tremendously increased blade life time in stainless steel pipe cutting (a lot, lot more cuts before the blade going dull) along with the special feature that avoids pipe contamination on vulnerable pipe surfaces – thanks to the parts touching pipe being made of stainless steel.

Last but not least, the new INOX pipe saw cuts stainless a lot faster than previous pipe cutter models as the technical specifications are made optimal for this type of materials.

So, actually how much faster is stainless pipe cutting with Exact if compared to an angle grinder?

Usually up to 10 times faster.

This time we wanted to test it in action and made a comparison of INOX 220 pipe saw and Angle Grinder.

The result?

See video below for the answer!

Why Is INOX 220 So Powerful At Cutting Stainless Steel Pipes & Tubes?

INOX 220 is the world’s first portable saw purely intended only for stainless steel pipe cutting. The machine has been invented with all the necessary features to optimize one goal: How to cut stainless steel pipes faster and more efficiently, while achieving a clean and straight cut – in the safest way possible.

Alright, then what are these features that make this machine reach the goal?

- Optimized RPM

- Powerful and robust motor

- The machine parts touching vulnerable stainless steel surfaces are also made of stainless steel to avoid pipe contamination

- Laser pointer for cutting point precision

- Equipped with a blade of cutting-edge technology from the world’s top blade engineers and in our cutting tests we were able to make over 100 cuts without re-sharpening the blade

- Other proven & best features from Exact machines

Lightweight Yet Versatile Way To Cut Stainless Steel

You will only have to carry the weight of 25 lbs (or 11.5 kg), and only for the duration you lift the machine up to the pipe. The machine itself loads most of the heavy straining, as the weight of the machine is supported by the pipe and ultimately by the pipe supports. This is a tremendous upgrade in working habits, if compared to other purely handheld power tools, such angle grinder and equivalent solutions.

Where Are Stainless Steel Pipes Used At?

- Food processing

- Textile operations

- Breweries

- Water treatment plants

- Oil and gas processing

- Fertilizers and pesticides

- Chemical applications

- Construction

- Pharmaceuticals

- Automotive components

Straight And Clean Cut Result With Only Minimal Burr

The resulting pipe end will be straight and clean with a nice 90-degree angle, with only a minimal or no burr at all.

Only Minimal Sparking From The Cutting

Normally when cutting stainless steel with a typical grinder-like method, the cutting process will produce excessive sparking that resembles mostly of fireworks show. This “fireworks effect” from typical grinders is extremely dangerous in terms of fire hazards, as the sparks have potential for setting any vulnerable surroundings on fire.

With Exact’s INOX 220 these types of risks are substantially lesser, as the sparking is minimal.

No Kickback From Cutting Stainless Steel (Unlike With Angle Grinder)

There are no kickbacks when using INOX 220 as per the operating instructions, thanks to the machine’s mechanics that grip tightly around the stainless pipe or tube.

Kickbacks are another possible and very serious risk while using an angle grinder to cut stainless steel, and really when cutting almost any pipe or object at all. When something is not firmly attached, the loss of concentration, tiredness, or any other reason, may cause prone for a kickback. The more unfortunate news is that according to scientific studies the most common sites injured are the head and face. The high speed disc of angle grinders does not respect anatomical boundaries or structures and thus the injuries produced can be disfiguring, permanently disabling or even fatal. Injuries resulting from the use of angle grinders are numerous.

“The Royal Society for the Prevention of Accidents’ Accident Surveillance Systems data ranked angle grinders as the third most dangerous tools, with 5400 injuries recorded annually” [1].

How To Cut Stainless With The Exact Method

This is the best part. Everything you will need is included in one package. The pipe supports holding the pipe, the machine, and the special saw blade. You won’t need to do any extra DIY modifications.

Obviously, you will also need an empty workspace, proper safety gear, obeying all the necessary safety rules.

Regardless if you are an expert or a beginner in this kind of work, INOX 220 is suitable for you.

Step 1. Prepare your workspace

Ensure that there is enough empty space at the place of cutting, no fire and health hazards around. Although this cutting method is a cold cut and thus produces only minimal sparking, it is very important to follow the safety precautions.

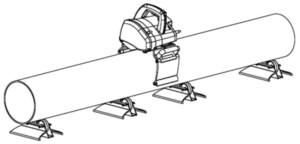

Step 2. Setting the pipe on pipe supports (or Pipe Bench)

Use the system supports when cutting pipes. Alternatively, you can use Exact Pipe Bench as shown in the above video. This will ensure safe working and optimum results. In this case, we focus working with the supports included in the package. Work on flat surface. Place the pipe on two supports so that the cutting point is between the supports. Place two more support under both ends of the pipe. Check that all support wheels contact the pipe. When cutting short and light weight pipes, place the supports so that the cutting point is outside supports. Support the pipe with your left leg, if required. Proper arrangements will prevent the blade from jamming as the pipe is cut through.

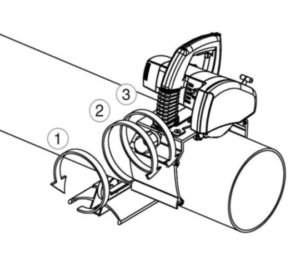

Step 3. Attaching the pipe saw to the pipe

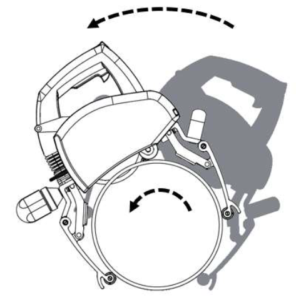

Open the pipe saw’s gripper unit enough to suit the diameter of the pipe by rotating the adjustment handle located at the rear of the saw. Position the pipe saw on top of the pipe so that the edge of the lower blade guard is at the cutting mark. Fasten the pipe saw to the pipe by turning the gripper adjustment handle until the gripper grips firmly the pipe to be cut. Lock the mechanism by tightening the gripper locking collar. Hold the pipe in place and ensure that pipe saw moves freely in the direction the pipe is fed. For the sake of safety ensure the pipe saw power cable is to the left of the pipe saw. The pipe saw is now ready for cutting.

Step 4. Cutting the stainless steel!

Hold the pipe saw operating handle firmly with your right hand and place your left foot on top of the pipe approximately 50 cm from the pipe saw. To start the motor, release the power-switch locking lever and push the power switch all the way in. Before starting to saw, pull back the lower blade guard handle and wait until the blade reaches full speed. Pierce the pipe wall by pressing pipe saw operating handle downwards slowly and steadily until the blade has cut through the pipe wall (during piercing the pipe must not rotate). Now you can safely start cutting around the pipe. Start cutting by feeding the pipe saw forward and at the same time preventing the pipe from turning, for example with your left foot. Feed the pipe saw forwards for convenient distance.

Step 5. Done!

The machine can now be unattached from the pipe, or repositioned for a new cut.

Please note: Always read the operating instructions before operating the machine.

Ready for better stainless steel cutting?